Share

Manufacturing, dating back to the Industrial Revolution, transforms raw materials into finished products through efficient methods, labor, and specialized equipment driving industrial growth and economic development. Today,

manufacturing

embraces digitalization, featuring technologies like AI, ML, and IoT, automating tasks, enhancing production, and elevating quality control.

Sustainability is another key trend, with manufacturers adopting eco-friendly practices with renewable energy and the use of sustainable materials. Additionally, additive manufacturing, exemplified by 3D printing, fosters customization and personalization, and on-demand production. These trends collectively shape the dynamic future of manufacturing.

Technological Transformation and Sustainability are Shaping the Future of Manufacturing

The future of the manufacturing industry is characterized by the integration of cutting-edge technologies, which are redefining production processes, elevating connectivity, and increasing transparency throughout the sector. At the same time, a dedicated emphasis on sustainable manufacturing practices is driving the implementation of eco-friendly processes, renewable energy sources, and sustainable materials. This harmonious blend of technology and sustainability is paving the way for a dynamic and socially responsible future in manufacturing.

Key trends

The Industrial Internet of Things (IIoT)

Manufacturing is in the midst of Industry 4.0, a transformation driven by the convergence of physical and digital technologies. The Internet of Things (IoT), artificial intelligence (AI), and big data are becoming essential to manufacturing processes. Smart factories equipped with sensors and data analytics provide real-time insights, boosting efficiency and reducing downtime. Manufacturers can now forecast maintenance needs, optimize production, and enhance quality control−ushering in a new age of productivity.

5G & Edge Computing

5G and Edge Computing are enabling real-time monitoring, predictive maintenance, remote operations, and real-time analytics. With 5G connectivity, sensors and devices on the factory floor can be connected and monitored in real time, facilitating quick problem identification. Simultaneously, Edge computing processes data in real time, offering actionable insights for enhanced efficiency and quality. By reducing network bandwidth demands, it reduces costs and improves application performance. Furthermore, it enhances data security and privacy by processing and storing data closer to its source, reducing the risk of breaches and unauthorized access.

Digital Twins

A digital twin serves as a virtual replica of a physical asset, process, or system, continually updated in real time through data collected from attached sensors and devices. Its impact on the future of manufacturing is significant, offering manufacturers a real-time perspective to enhance efficiency by identifying and eliminating production bottlenecks, optimizing schedules, and reducing waste. Moreover, digital twins monitor product quality throughout production, facilitating early issue identification and correction. They also play a crucial role in reducing downtime by predicting maintenance needs, enabling proactive scheduling to prevent costly disruptions. Digital twins also serve as invaluable tools for simulating the performance of new products and services in a virtual environment, allowing manufacturers to preemptively address potential issues before launching innovations.

Blockchain Technology

Blockchain is revolutionizing the manufacturing industry in multiple ways. Firstly, it enhances supply chain transparency and traceability by tracking materials and products throughout the supply chain, reducing fraud and enabling early issue detection. It also facilitates novel business models, such as decentralized manufacturing networks, promoting resource sharing and collaborative projects without central intermediaries, thereby streamlining manufacturing operations. This transformative technology makes manufacturing more efficient, productive, and cost-effective by improving transparency, enabling innovative business approaches, and creating new manufacturing applications.

Sustainability, ESG, and Social Responsibility

Sustainability, Environmental, Social, and Governance (ESG) considerations, and social responsibility are profoundly influencing the future of manufacturing. Manufacturers are adopting eco-friendly operations, sustainable supply chains, and responsible product development. Compliance with ESG standards and stringent environmental regulations is becoming imperative, and ethical practices in community engagement and labor are emphasized. As consumers increasingly value sustainability, responsible manufacturing is not only ethical but also economically advantageous by enhancing a company's reputation and competitive edge.

Navigating the Future: Challenges and Considerations in Manufacturing

While the future of manufacturing brings promise, it comes with challenges. Embracing emerging technologies unlocks new opportunities. Addressing these challenges head-on positions manufacturers for a prosperous future:

Technology Adoption and Integration

The rapid pace of technological advancement in manufacturing requires companies to continually adopt and integrate new tools and systems. This can be challenging, especially for smaller manufacturers with limited resources.

Shortage of Skilled Workforce

The manufacturing sector grapples with a dual challenge: a significant loss of approximately 1.4 million jobs due to Covid compounded an existing labor shortage. Projections indicate an alarming gap of 2.1 million unfilled positions by 2030, primarily attributable to a scarcity of skilled labor. Preparing the future workforce for success demands proficiency in advanced technologies and digital tools, necessitating substantial investments in workforce development and training.

Globalizing Supply Chains

The process of globalizing supply chains faces dynamic challenges, including geopolitical shifts among global superpowers and conflicts between nations, intensified competition from countries offering lower labor costs and more relaxed environmental regulations, and a pronounced disruption catalyzed by the Covid pandemic.

Data Management and Cybersecurity

In an era of increasing connectivity and digital reliance within manufacturing, protecting against cyberattacks and data breaches is of paramount importance. Safeguarding sensitive data and intellectual property is a critical consideration. Simultaneously, efficiently managing the copious data generated by IoT devices and digital twins necessitates robust storage, processing, and analytical capabilities.

Reducing Environmental Impact

Manufacturers need to reduce their environmental impact to meet growing customer demand for sustainable products. This will involve investing in new technologies and processes that are more sustainable.

Customization vs. Mass Production

Balancing the demand for customized products with efficient mass production is a challenge. Manufacturers need to find ways to offer personalization while maintaining cost-effectiveness.

Private Equity Investments Impacting the Future of Manufacturing

Private equity firms are investing heavily in companies that are developing and utilizing new technologies to transform the manufacturing industry. PE firms are attracted to the manufacturing industry because it is a large and growing sector with several aging assets. This creates opportunities for PE firms to invest in companies that are developing new technologies and services to help manufacturers improve their efficiency, productivity, and sustainability.

Stax has deep expertise within the manufacturing industry, providing invaluable insights to both investors and businesses alike. Project-related experience includes comprehensive market analyses, identifying promising investment opportunities, and delivering data-driven insights. The firm serves a diverse range of investor interests, with a particular emphasis on upstream assets, including input suppliers and manufacturers. With a profound understanding of the ecosystem, Stax stands as the leading strategy consulting firm for comprehensive market outlooks and stability trends.

Conclusion

Stax is a global strategy consulting firm with extensive experience in

the manufacturing industry and withing Industrials. Across several engagements we've advised on, Stax has identified platforms for growth, assessed bolt-on acquisition opportunities, and ultimately helped position the companies for sale. To learn more about Stax and our expertise, visit

www.stax.com or

click here to contact us directly.

Sources

- Ellström, Magnus, Emma Sandin and Adam Reeb. “Is your digital strategy fit for the manufacturing future?” EY, Mar. 2023.

- Hagel III, John, John Seely Brown, Duleesha Kulasooriya, Craig Gif and Mengmeng Chen. “The future of manufacturing: Making things in a changing world,” Deloitte University Press, Apr. 2015.

- Gavin, Adam. “The future of manufacturing: insights from industry leaders on navigating the Fourth Industrial Revolution,” World Economic Forum, Jun. 2023.

- Marr, Bernard. “The 10 Biggest Future Trends In Manufacturing,” Forbes, Jan. 2022.

- Meng Tan, Chor. “How The Manufacturing Industry Can Create Capabilities In The Workforce Of Tomorrow,” Forbes, Mar. 2022.

- Caldwell, Lisa. “Responsibility And Opportunity: How Manufacturers Can Get Ahead Of The Game On ESG,” Forbes, Mar. 2022.

- Lindquist, Margaret. “Top 5 Industrial Manufacturing Trends in 2023,” Oracle, Jul. 2023.

- Maria Negron Kneib, Mapi. “Intersecting Sustainability: ESG and Smart Manufacturing Trends," MAPI, Jan. 2020.

- GE. “GE Announces Predix Cloud - The World's First Cloud Service Built for Industrial Data and Analytics,” GE, Aug. 2015.

- NIX. “Top 10 Industrial IoT Applications with Reali-life Examples,” Nix, Aug. 2023.

- DaviTeq. “I4.0: Technology Adoption & Challenges for Manufacturing,” DaviTeq, Oct. 2020.

- Van de Groep, Gertjan. “Navigating the Challenges of the Manufacturing Industry in 2023 and Beyond,” IESF, Jun. 2023.

- Feraday, Stephanie. “Top-7 Manufacturing Challenges for 2023,” aPriori, Dec. 2022.

- Grundy, Adam. “Diversity, Equity and Inclusion Key to Filling High-Skilled Manufacturing Jobs,” United States Census Bureau, Sep. 2023.

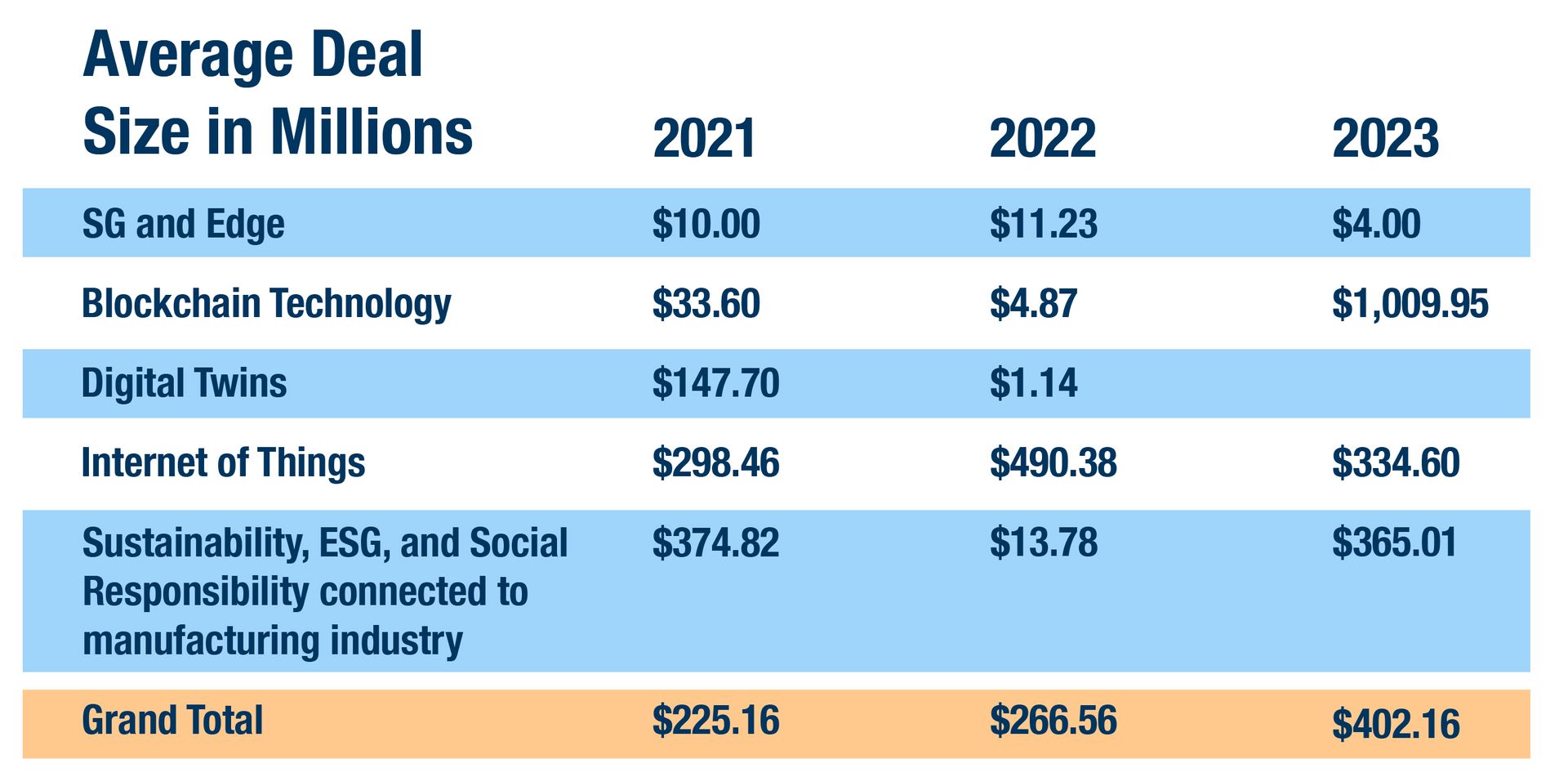

- Pitchbook: Stax analysis. “PE deals in 5G, Blockchain, Digital Twins, IOT, ESG, & ESR related Manufacturing,”

Pitchbook: Stax analysis, Nov. 2023.